Home page

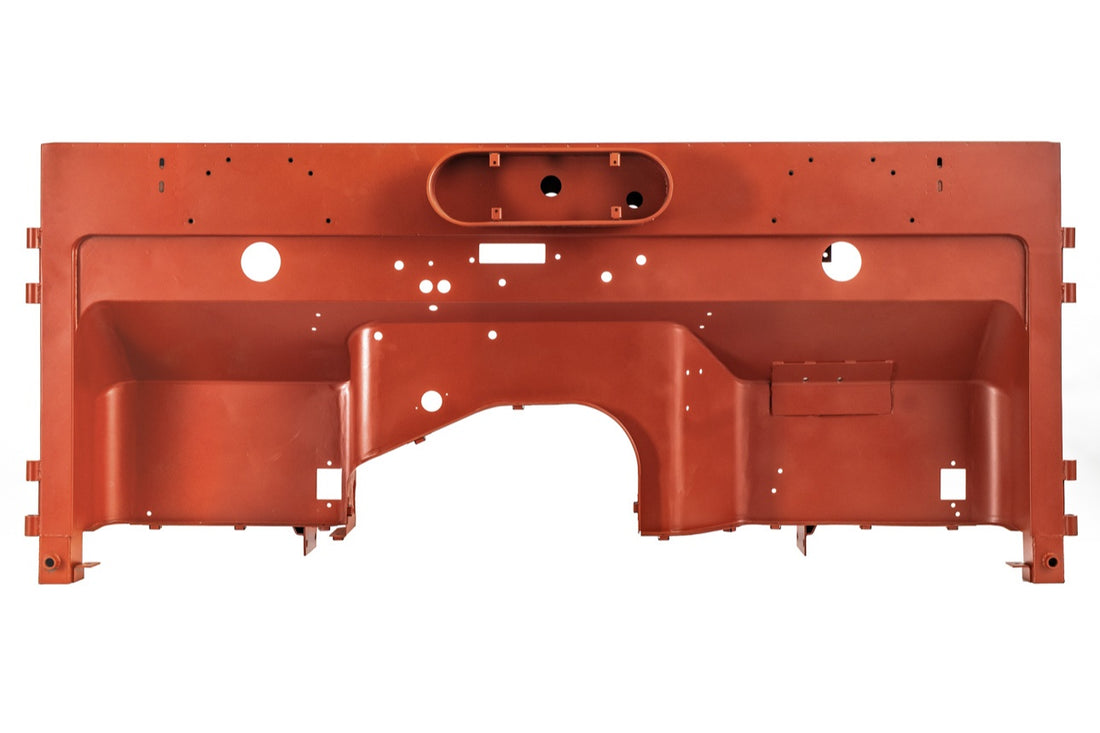

301061 (TYPE 1) - Bulkhead, 80", Late 1948 to Late 1949

Handmade In The UK

Our Process

Individual Components

We utilize our own designs and patterns to cut and shape the final parts. We have invested in advanced tooling to create a bulkhead that is comparable to Rover's original engineering. Pegasus have extensive experience in sheet metal work and are able to replicate all original pressing details, holes, spire nut locations, and footwell ribs.

Made Stiffer, Stronger and Corrosion-free

Our parts are fabricated with minimal pressing, preserving metal thickness. Using modern design and materials, we have improved performance by strengthening and stiffening weak points by 50% compared to the original bulkhead. This means that not only does the bulkhead maintain its original appearance, but it is also more durable and long-lasting.

Spot Welded Like The Originals

Pegasus bulkheads are constructed using the same spot welding method as the original bulkheads. The majority of the parts are joined together using spot or TIG welding to create sub-assemblies, which are then assembled into the final assembly. To ensure precise bulkhead geometry, the assembly is constructed on a 36 reference point jigs.

Final Stage Welded

Pegasus utilize TIG welding on the final assembly for heavy-duty brackets, lap joints, and butt joints. The heavy-duty brackets such as the bonnet hinges, tie rod brackets, and bottom feet are also welded into place using TIG welding to replicate the original oxy-acetylene welding method. We maintain the highest standards in our manufacturing process and have complete control over the quality of each finished bulkhead.

Kind Words From Our Customers